Updated: August 7, 2024

The following questions and answers should hopefully tell you all you need to know about cyanoacrylate including its chemical makeup, applications, unique properties, and more.

Jump to:

- What is CA glue?

- What is the difference between cyanoacrylate adhesive and super glue?

- What types of cyanoacrylates are there?

- How does cyanoacrylate cure?

- How long is the shelf life of cyanoacrylate?

- What is the average cure time of cyanoacrylate?

- Why does super glue stick to almost everything?

- What surface preparation do I need for cyanoacrylate adhesives?

- Can I use cyanoacrylate glue to bond porous surfaces like paper or leather?

- Can I use cyanoacrylate on flexible surfaces and rubber?

- How do you get super glue off your fingers?

- How do I remove super glue from plastic, fabric, or other surfaces?

- Are there two-part cyanoacrylates?

- What is cyanoacrylate gel?

- What is a toughened cyanoacrylate?

- At what temperature can cyanoacrylate be used?

- When should primer be used with cyanoacrylate adhesives?

- When should an accelerator be used with cyanoacrylate adhesives?

What is CA glue?

In its simplest form, cyanoacrylate adhesive (CA) is super glue — a quick-drying, strong-bonding clear adhesive. It takes the shape of a polymer (plastic) resin in its cured form and a monomer in its uncured form. This family of adhesives is also sometimes called instant adhesives.

What is the difference between cyanoacrylate adhesive and super glue?

While the two terms are used interchangeably, there is a subtle difference. Super glue is a generic term that refers to certain types of cyanoacrylates that the everyday user is most likely to find at the store. It comes from the registered trade name Loctite popularized under distribution rights from the original patent holder Eastman Kodak.

Altogether, the cyanoacrylate family of glues includes fast-drying, strong-bonding adhesives that have industrial, household, and even medical applications. While the general chemical makeup is the same, there are differences in performance and unique properties for various products that fall into this category.

Different people will also refer to these products in different ways. Typically, household users looking to make a quick repair will be able to find a basic cyanoacrylate at their local store and will refer to it as super glue. Craftspeople may use a higher-grade adhesive to achieve greater bond strength that they may be able to find online or at a specialty store. They may also use the more technical term of cyanoacrylate. Finally, manufacturers will often need industrial-level adhesive and are the most likely to use the technical terms for this family of glues.

What types of cyanoacrylate are there?

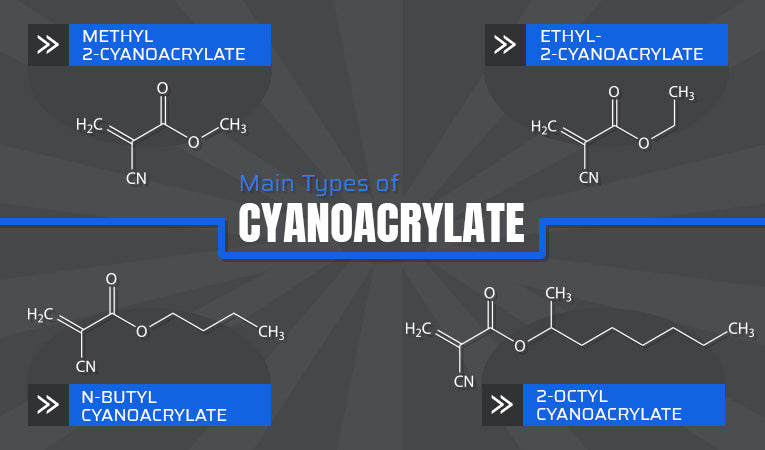

Two types of cyanoacrylates are methyl 2-cyanoacrylate and ethyl-2-cyanoacrylate (referred to by the generic term super glue). There is also n-butyl cyanoacrylate and 2-octyl cyanoacrylate that are both used in medical applications.

How does cyanoacrylate cure?

Unlike some adhesives that cure by evaporation or heat, cyanoacrylates cure almost instantly from reacting with moisture in the air, providing there is even just a small amount of relative humidity in the atmosphere.

How long is the shelf life of cyanoacrylate?

Cyanoacrylate has a maximum shelf life of 12 months if unopened and around 4 to 8 weeks if opened. This shelf life will vary with product type as well as manufacturing and storage environments, but these figures are a good guideline for most cyanoacrylate products.

What is the average cure time of cyanoacrylate?

The average cure time of cyanoacrylate adhesives is anywhere from 5 to 90 seconds for a fixture and from 8 to 24 hours for full curing. The cure time will depend on the surfaces engaged and their moisture absorption qualities as well as the type of cyanoacrylate used. We think of super glue as a super fast curing glue, but there are fast and even faster types of cyanoacrylates. Surface insensitive types, for example, are super-fast curing, toughened types, and hybrid epoxies are slightly slower curing.

Why does super glue stick to almost everything?

Super glue is so sticky because of its moisture-curing process. Cyanoacrylate adhesives cure when exposed to moisture, and since there is moisture almost everywhere, they react well on almost every surface. Even for difficult surfaces like those that repel water, there are modified cyanoacrylates like surface insensitive cyanoacrylates and cyanoacrylate gels.

What surface preparation do I need for cyanoacrylate adhesives?

Proper surface preparation for cyanoacrylate glues should include cleaning the substrates to ensure they are free of grease, oil, dust, and other contaminants. You may need to apply a solvent or primer for this process. Surfaces should also be dry before application.

Can I use cyanoacrylate glue to bond porous surfaces like paper or leather?

Yes, cyanoacrylate gel adhesives work best for porous surfaces since they fill the small gaps between the surfaces far better. The Infinity Bond Surface Insensitive Cyanoacrylate is a product that is good for these types of applications.

Can I use cyanoacrylate on flexible surfaces and rubber?

Yes. Flexible cyanoacrylates are available with rubber additives for applications where movement may affect the joint. For active environments that require a flexible bond, we recommend the Infinity Bond Rubber Toughened CA Glue.

How do you get super glue off your fingers?

Painfully! Super glue loves the moisture content in our skin, so much so that you might find yourself gluing your fingers instead of your target. To get super glue off your fingers, a pen or pencil point forced between the bond can help, as super glue weakens with shear loads (a ton can be lifted horizontally but putting the same joint under side loads it will break easily). If this doesn't work, acetone is one of the best home-based solvents for cyanoacrylate.

How do I remove super glue from plastic, fabric, or other surfaces?

If you get it somewhere you do not want it, you can remove super glue with a solvent, special cyanoacrylate remover, or prolonged soaking in soapy water. Care should be taken when applying solvents to plastic as the solvent can eat away at the base material in the same way it removes the glue. In this case, it may be better to attempt prolonged soaking with soap and water for several hours. This process takes more time but will eventually soften the glue, so it will come off easier.

Are there two-part cyanoacrylates?

Yes, they are hybrid cyanoacrylates which are two-part. The Loctite HY 4090 hybrid is one example of a two-part cyanoacrylate epoxy hybrid, and the Loctite 3092 is a urethane cyanoacrylate. The combination provides the high strength of cyanoacrylate with the good structural strength and elasticity of other adhesives. Hybrid cyanoacrylates also provide gap filling qualities and easier bonding of rough surfaces that lower viscosity cyanoacrylates don't provide.

What is cyanoacrylate gel?

Cyanoacrylate gel is a high viscosity product that adheres well to porous surfaces. Most basic cyanoacrylates have a very low viscosity which can make handling difficult. Trying to adhere a low viscosity product to a rough surface or a vertical wall, for example, is like trying to fill a cream cake with liquid cream. Cyanoacrylate gels, on the other hand, adhere to surfaces where resistance against gravity is needed or where the glue needs to fill surface gaps.

What is a toughened cyanoacrylate?

A toughened cyanoacrylate has an additive like rubber to increase its shear strength. They do take slightly longer to cure than normal super glues and may need an accelerator if fast cure times are needed.

At what temperatures can cyanoacrylate be used?

Most cyanoacrylates can be used up to 200 degrees Fahrenheit, but some special applications can go up to 275 degrees Fahrenheit. If you are using cyanoacrylate in extreme heat, look for a special high-heat product designed to withstand those higher temperatures.

When should a primer be used with cyanoacrylate adhesives?

Use a primer with cyanoacrylate when you are dealing with inactive surfaces or the product’s technical datasheet suggests it. An adhesive primer prepares the substrate for better adhesion and can be used to help bond on inactive surfaces. Primers may not work on all surfaces, so always consult the manufacturer's guide.

When should an accelerator be used with cyanoacrylate adhesives?

Use an accelerator with cyanoacrylate when you need to increase the cure speed or are doing gap-filling. Especially in cold, dry conditions, a special-purpose accelerator can help.

Still Have Questions?

If you have further questions about cyanoacrylate adhesives or would like to talk to a specialist about your specific application, contact us. One of our knowledgeable team members would be happy to assist you.